I. Introduction

In our increasingly interconnected world, electronics play a pivotal role in powering and connecting various devices. These electronics rely on the integration of multiple components and the interconnection of intricate circuits. Traditional rigid printed circuit boards (PCBs) have long been the standard, but as devices become smaller and more complex, the need for flexible and adaptable solutions has grown. This has led to the rise of FPCs, or Flexible Printed Circuits. In this article, we will explore the world of FPCs, their construction, applications, advantages, and the pivotal role they play in modern electronics.

II. What Are FPCs?

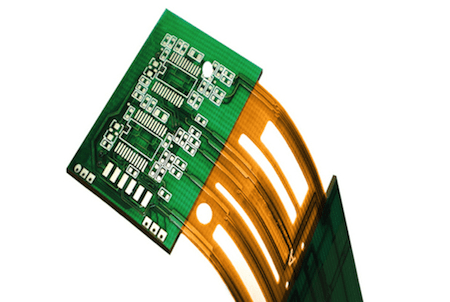

Flexible Printed Circuits (FPCs), also known as flex circuits, are a type of printed circuit board that differs from the conventional rigid PCBs. FPCs are designed to be highly flexible and adaptable, making them ideal for applications where traditional rigid boards would not suffice. They are typically made from a thin, flexible substrate material, such as polyimide or polyester, and utilize conductive traces to create electronic connections. These traces are often made of copper, providing the necessary conductivity.

The core characteristic of FPCs is their ability to bend, twist, and conform to irregular shapes without losing functionality. This flexibility enables engineers to design and integrate electronic components into tight and unconventional spaces, making FPCs an essential tool in modern electronics.

III. Construction of FPCs

The construction of FPCs is a multi-step process that involves the creation of a flexible substrate and the deposition of conductive traces. Here are the key components and steps in FPC manufacturing:

Substrate Material: FPCs are built on flexible substrate materials, with polyimide and polyester being the most common choices. These materials offer a balance of flexibility, durability, and thermal resistance, making them suitable for a wide range of applications.

Adhesive Layer: An adhesive layer is often applied to one side of the substrate to facilitate the attachment of electronic components.

Copper Traces: Conductive traces, typically made of copper, are patterned onto the substrate using processes such as etching or additive printing. These traces carry electrical signals and connect various components on the FPC.

Coverlay: To protect the conductive traces and the substrate, a coverlay, often made of polyimide, is applied to the FPC’s surface. The coverlay serves as a dielectric material and safeguards against environmental factors like moisture and dust.

Stiffeners: In certain applications, stiffeners or support layers may be added to specific areas of the FPC to enhance rigidity. Stiffeners are crucial when components need additional support or when the FPC must interface with connectors.

Connectors: Connectors are attached to the FPC to establish connections with other electronic components or PCBs. They can be soldered, press-fitted, or employ other connection methods, depending on the application.

Solder Mask: A solder mask is applied to protect the exposed copper traces from oxidation and to help control the flow of solder during assembly.

The combination of these components and steps results in a flexible and reliable circuit that can perform various functions in a multitude of applications.

IV. Applications of FPCs

FPCs have made their mark in a wide array of applications across different industries due to their flexibility and adaptability. Some of the key applications include:

Consumer Electronics: FPCs are used extensively in smartphones, tablets, and wearable devices, where space constraints and flexibility are critical design factors.

Automotive Electronics: In modern vehicles, FPCs are found in instrument clusters, infotainment systems, airbags, and sensors. They can withstand temperature variations and mechanical stress while delivering reliable performance.

Medical Devices: The medical industry benefits from FPCs in devices like endoscopes, pacemakers, and diagnostic equipment. Their flexibility and ability to conform to the human body make them invaluable in these applications.

Aerospace and Defense: In aerospace and defense applications, FPCs play a role in avionics, radar systems, and military communications equipment. Their lightweight and durable construction are particularly advantageous in these demanding environments.

Industrial Automation: Industrial automation equipment, including robotic systems and control panels, often incorporates FPCs for their compact design and resistance to vibrations and shock.

Communication Systems: FPCs are used in communication systems, such as routers, switches, and data transmission devices. Their adaptability allows for efficient use of space and can withstand the demands of data communication.

LED Lighting: FPCs are employed in LED lighting solutions, where they can be shaped to fit specific designs and provide efficient heat dissipation.

IoT Devices: The Internet of Things (IoT) relies on compact and adaptable electronics. FPCs are integral to various IoT devices, enabling connectivity and sensor integration.

Aerospace: In the aerospace industry, FPCs find applications in avionics, where they can withstand extreme temperatures, vibrations, and mechanical stress.

V. Advantages of FPCs

FPCs offer numerous advantages over traditional rigid PCBs, making them an attractive choice for many applications:

Flexibility: FPCs are highly flexible and can be bent or twisted to conform to the shape of the device or housing. This adaptability enables design creativity and efficient use of space.

Space-saving: FPCs are thin and lightweight, allowing for compact designs that can be particularly advantageous in miniaturized electronics.

Weight Reduction: The use of lightweight materials in FPC construction can lead to weight reduction in devices and systems, making them more portable and energy-efficient.

Durability: FPCs are resilient and can withstand mechanical stress, vibrations, and temperature variations, ensuring their reliability in challenging environments.

Reliable Connections: FPCs offer reliable interconnections that minimize the risk of solder joints breaking or becoming dislodged.

Heat Dissipation: The flexibility of FPCs allows for efficient heat dissipation, making them suitable for applications that require cooling.

Reduced Assembly: FPCs can reduce the number of assembly steps and connectors in a device, simplifying manufacturing processes.

Customization: FPCs can be customized to specific shapes and sizes, making them ideal for unique or specialized applications.

Resistance to Environmental Factors: FPCs can be designed to be resistant to moisture, dust, and chemical exposure, enhancing their longevity in harsh environments.

Reliability: FPCs offer high reliability, reducing the risk of signal loss or failure, making them suitable for mission-critical applications.

VI. Challenges and Considerations

While FPCs offer numerous advantages, there are also challenges and considerations to keep in mind:

Cost: FPCs can be more expensive to manufacture compared to traditional rigid PCBs, which can impact the overall cost of electronic devices.

Design Complexity: Designing with FPCs can be more complex, requiring specialized knowledge and tools.

Limited Bend Radius: FPCs have a specified minimum bend radius, and bending beyond this limit can cause damage to the circuit.

Specialized Manufacturing: Manufacturing FPCs involves unique processes, so working with a reputable manufacturer is essential for quality and reliability.

Testing: Testing FPCs for defects can be more challenging due to their flexibility.

Material Selection: Choosing the appropriate substrate material and other components